- Luoyang Deping Technology Co., Ltd

- Main products: pipeline equipment, pipe external auto welding machine, pipe internal welding machine, pipe external lind up clamp, pipe internal lind up clamp with copper backing shoe, pipe paywelder, pipe roller cradle, pipe bend mandrel, pipe preheater, pipe cutting beveling machine, pipe facing machine

Home > Company News > Deping high performance pipe lowering in Pipe roller cradles

Company News

Deping’s Pipe Roller Cradle Process Control2021-10-20

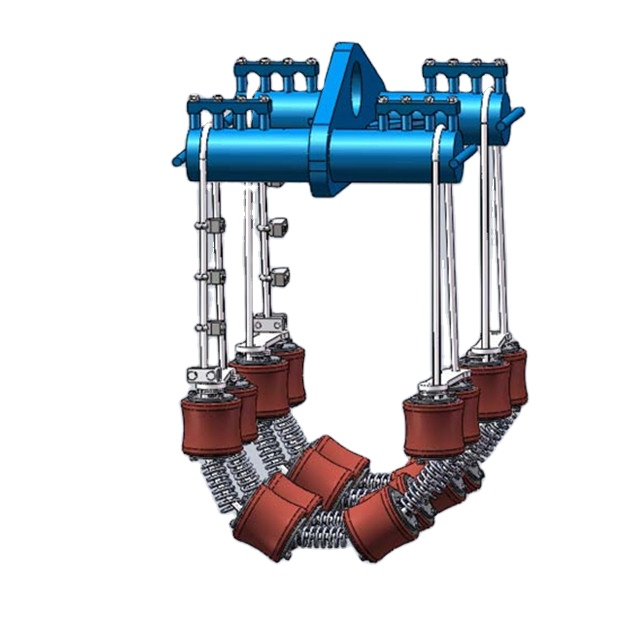

Pipe roller cradles are for pipe lowering in trench purpose, major factors as follows:

1. Lifting capacity, it depends on beam material, beam welding and steel rope etc

2. Lifting safety factor: 5:1 is recommended

3. Roller coating life time: urethane rollers eliminates the risk of damage to the pipe

Lifting beam:

Deping adopts high strength welding steel as hanger material to ensure welding seam strength

Beam welding processes:

Strictly follow the prequalified welding parameters, and conduct 100% NDT test to ensure safe use of roller cradle

Roller coating processes:

Key factors for roller lifetime: coating process and coating thickness.

To prevent coating peeling out, Deping well organize the coating process of pipe roller cradle, including: metal roller polishing, sand blasting, 2 times of ultrasonic cleaning, drying, applying glue, heating treatment in oven, keep dry and metal roller at constant high temperature for coating, coating vulcanization for 24hours etc.

Furthermore several coating tests will be conducted per standard DIN53505 or GB/T 528-2009, including Hardness shore A, Max. broken pulling force / N, Tensile strength / MPA, Elongation at break / %, Peel strength / N/mm etc.

Deping’s pipe roller cradles comply with European standards, obtain CE certification.

Any inquiry, welcome to contact us!

Popular Searches

- Duct Production Line

- Auto Duct Line

- cement pipe production line

- cement pipe machine

- spiral duct making machine

- spiral tubeformer

- tube mill

- tube making machine

- pipe mill

- Steel Pipe Making Machine

- seam line welding

- welding making machine

- tube welding machine

- welded tube line

- tube making equipment

- Spiral Forming Machine