ADVANTAGES OF USING A PULSED MIG WELDER

When MIG welding was first invented, it used a constant voltage source of electricity for the arc. While this method is still used today, the invention of pulsed MIG (or MIG pulse) welding has allowed welders to realize several advantages over conventional MIG welding, several are listed below:

Easy setup is a key feature with modern pulsed welding power sources. There is an option to have one-knob control to help operators set the parameters they need so that they don’t have to be an expert to get a good arc.

Reduced spatter generated by the pulsed MIG process means less time and money spent on grinding and post-weld cleanup for a positive impact on the bottom line.

Excellent directional control over the weld pool makes it easier for new welders to learn the process and create welds with good bead appearance. Deping automatic orbital welding machine has built-in adaptive technology that allows welders with less experience to produce quality welds more consistently.

Faster wire feed and travel speeds help increase productivity while reducing heat input and the risk of distortion and burn-through. This makes pulsed MIG a good option for welding materials like stainless steel that require lower heat input to maintain certain properties.

Improved control over arc starts and stops helps reduce weld defects and improve bead appearance. The process provides higher energy when the arc is first initiated, which provides good fusion, and the energy is then reduced going into the weld to help prevent burn-through and give the operator more control over bead appearance. When stopping the arc, a pulsed MIG process with a crater function allows the welder to ramp down to cooler parameters to fill in the crater at the end, eliminating the potential for termination cracking that can occur when welding materials such as aluminum.

Adjustable arc cone width, a feature available with Deping automatic orbital welding machine, helps prevent over-welding and poor fusion because the operator can tailor the bead profile to the application. Wider weld beads help improve tie-in on both sides of the joint, while narrower beads offer good fusion at the joint root.

Getting better results with pulsed MIG

Pulsed MIG welding provides faster travel speeds, reduced spatter levels and improved control over arc starts compared to CV MIG, making it a good option for fabricators that want to boost efficiencies or improve weld quality. With some training and a little practice, welders of all skill levels can master pulsed MIG welding and optimize productivity and efficiency with the process.

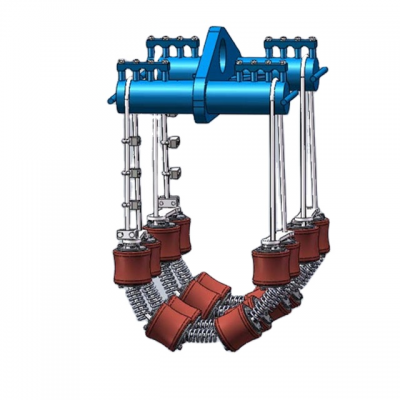

Deping automatic orbital welding machine adopt pulse MIG welding, with arc crossing and height automatic tracking, it is easy to learn operation and very helpful for pipeline construction.

Recently Posted

-

Manual thread screw-rod-type external pipe line-up clamp for pipeline welding alighment

December 26, 2025Screw-rod-type external pipe line-up clamp Mostly applicable for 2〞-60〞 pipe jointing operation. Feature: easy operation, hig Read More

Read More -

Deping pipe roller cradle

January 12, 2022Pipe roller cradles are for pipe lowering in trench purpose, major factors as follows:1. Lifting capacity, it depends on beam mate Read More

Read More -

What makes the perfect bevel shapes?

January 12, 2022What makes the perfect bevel shapes?The experience we have provide equipment in pipeline projects more than 50 countries around th Read More

Read More -

Deping high performance pipe lowering in Pipe roller cradles

October 22, 2021Deping’s Pipe Roller Cradle Process Control2021-10-20Pipe roller cradles are for pipe lowering in trench purpose, major factors as Read More

Read More